To ensure optimal performance and extend the life of the filter, proper maintenance is crucial. This guide details how to properly inspect, clean, and replace Pleated Filter Cartridges to help you manage filters efficiently.

1. Regular Inspection

Regular inspections help managers detect potential issues early, preventing system failures or contamination of the filtered solution. Key inspection points include:

A. Visual Inspection

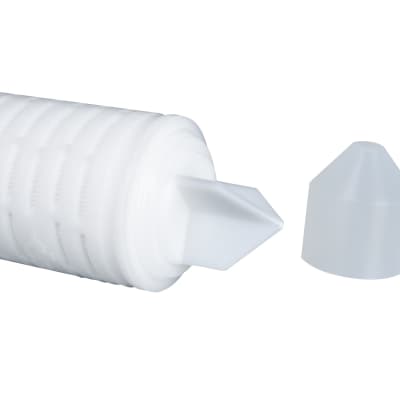

Observe if there is any noticeable dirt buildup on the wrinkles of the filter. If the filter is too dark or clogged, clean or replace it promptly.

Check the wrinkles and seal edges for any tears, damage, or deformation. If found, replace the filter immediately to prevent contaminants from bypassing the filtration system and reducing its efficiency.

B. Pressure Differential Monitoring

Use a pressure gauge to check the pressure differential between the incoming and outgoing flow. If the pressure difference is significantly lower than 0.1 MPa, remove the filter from the housing after shutdown for cleaning or replacement.

Specific method:

① Rinse the filter surface with clean water.

② Soak the filter in a 4% hydrochloric acid solution for 0.5-1 hour.

③ Soak the filter in a 4% NaOH solution for 24 hours.

④ Rinse with clean water and air-dry.

2. Cleaning and Disinfection of Wrinkle Filters

A. Water Rinse

Use low-pressure water flow to rinse dust and debris from the filter surface. Reverse flow (opposite to the normal direction) is more effective and can more thoroughly remove attached particles.

B. Soaking Cleaning

① Alkaline Solution Cleaning: Common alkalies include sodium hydroxide, potassium hydroxide, and sodium carbonate. The pH of the alkaline solution depends on the filter material, typically between pH 10-12. Circulation or soaking for 0.5-1 hour followed by cleaning can effectively remove impurities and grease.

② Oxidizer Cleaning: Clean the filter with 1%-3% H2O2 or 500-1000 mg/L NaClO solutions to remove dirt, oxidize, and kill bacteria. H2O2 and NaClO are commonly used disinfectants.

③ Acid Solution Cleaning: 1-2% citric acid solution or 0.1N oxalic acid solution or 0.1N hydrochloric acid solution mixture with pH = 2-3, soak for 0.5-1 hour and clean by circulation. This is effective for removing inorganic impurities.

④ Other Cleaning Solvents, such as enzyme solutions. It is recommended to maintain a cleaning temperature of 30-40°C. Enzyme detergents, such as 0.5%-1.5% pepsin or trypsin, can effectively remove protein, polysaccharide, and grease contaminants.

Caution: For filters used in high-protein filtrates, such as unfiltered beer or nutrient solutions, perform high-temperature disinfection after cleaning to prevent protein coagulation, which could block filter membrane pores.

C. Reverse Flushing

Typically, reverse flushing is used in production lines. Close the feed and filtrate pipes and flush with sterile water, inputting from the original outlet and draining from the water inlet or the filter’s bottom drain. Reverse flushing should be pressurized, but not too high—usually controlled at around 5 kg.

3. Storage and Handling of Filters

To prevent damage and contamination, pay attention to the following:

Avoid excessive bending, twisting, or compressing the filter, as this can affect filtration performance.

Store filters in a clean, dry environment, avoiding moisture, dust, and direct sunlight.

Store spare filters in sealed packaging to prevent contamination.