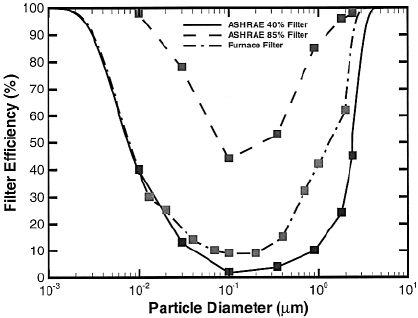

High-efficiency filters are currently the most popular purification devices and are an essential part of industrial environmental protection. Their main feature is their ability to effectively capture fine particles ranging from 0.1 to 0.5 microns, and they also perform excellently in filtering other pollutants. This makes them a crucial component in enhancing environmental safety.

The filter layer of a high-efficiency filter captures particles in four main ways, ensuring extremely high filtration efficiency and providing a clean environment for various industrial applications. Below are the four primary mechanisms by which high-efficiency filters operate:

1.Interception Effect:

When particles of a certain size approach the surface of the filter fibers, if the distance between the particle's radius and the fiber surface is smaller than the particle's radius, the particles will be intercepted by the fibers and deposited. This mechanism is particularly effective for trapping larger particles.

2.Inertia Effect:

Particles with larger mass or higher velocity, due to their inertia, cannot follow the direction changes of the airflow and will eventually deposit on the surface of the filter fibers. This effect is particularly effective for larger particles, such as dust or dirt.

3.Electrostatic Effect:

Filter fibers or particles may carry an electric charge, leading to electrostatic attraction. Charged filter fibers attract and adsorb particles with opposite charges, further improving filtration efficiency. This principle is particularly important for capturing fine particles and microorganisms.

4.Diffusion Motion:

For smaller particles, Brownian motion is stronger, causing the particles to collide with the fiber surface and deposit. This effect is primarily effective for micro-sized particles, especially for those below 0.1 microns.

As the number of particles in the filter layer increases, the efficiency of the filter gradually decreases, and the resistance increases. When the resistance reaches a certain level, the filter should be replaced promptly to ensure the purity of air or liquid and the efficiency of the system.

Characteristics of High-Efficiency Filters:

Common high-efficiency filters typically use an aluminum alloy frame with a no-partition design. This structure not only provides excellent sealing but also prevents filter leakage, ensuring stable operation. Industrial-grade high-efficiency filters are designed to be more resistant to corrosion and high temperatures, making them suitable for harsher working environments.

The filtering material of HEPA (High-Efficiency Particulate Air) filters is usually made of ultra-fine glass fiber paper, which can capture almost all tiny particles, ensuring that no small pollutants are missed. This contributes to a cleaner environment and safer industrial production processes.

Applications and Performance of High-Efficiency Filters:

Under normal operating conditions, the maximum operating efficiency of high-efficiency filters can reach 99.999% for 0.3-micron particles. Due to their outstanding efficiency, HEPA filters are widely used in various industries, particularly in pharmaceutical filtration, food processing filtration, and electronics manufacturing. Their exceptional performance plays a vital role in ensuring air quality, improving product quality, and protecting workers' health.

In summary, high-efficiency filters achieve extremely high filtration efficiency through various particle capture mechanisms, meeting the growing demand for clean environments in modern industries. They are widely applied in various fields, becoming crucial equipment for ensuring production quality and environmental hygiene.