In the food industry, a hygienic production environment is a prerequisite for successful manufacturing. By controlling and monitoring air quality (temperature, humidity, and particle concentration), product contamination can be minimized. Additionally, a clean air environment helps protect employee health. To create a space that meets standards for cleanliness, a range of specialized purification equipment is essential. Therefore, dust-free rooms capable of achieving extremely low particle concentrations in the air are becoming increasingly valued by food factories.

The most basic line of defense in food factory cleanrooms is the primary air filter. Working in conjunction with the ventilation system, it effectively captures larger dust particles in the air, such as those larger than 5 microns, including dust, fibers, and other impurities. Generally, the filtration efficiency of primary filters ranges from 50% to 80%. These filters are typically made of nonwoven fabric or metal mesh and serve the vital role of initially purifying the air before it reaches subsequent systems, preventing large particles from damaging equipment and reducing the pressure on downstream filters.

The medium-efficiency air filter plays a crucial role in further enhancing air cleanliness. With a filtration accuracy between 1 to 5 microns, it can filter out smaller particles like pollen and bacteria, with filtration efficiency exceeding 70% to 90%. Made from fiberglass or synthetic fiber materials, medium-efficiency filters help remove some microorganisms after the initial filtration, ensuring the hygienic safety of the food production environment.

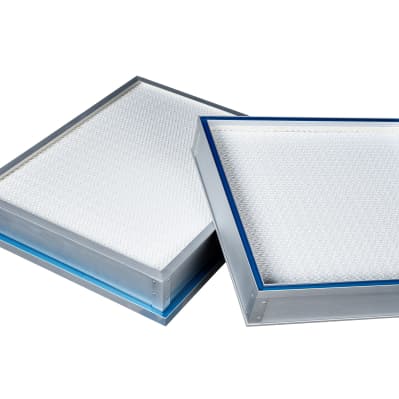

High-efficiency air filters are one of the core components of the cleanroom in food factories. For particles as small as 0.3 microns or smaller, high-efficiency filters can achieve filtration efficiencies of over 99.99%. This means they can almost completely block extremely small contaminants, such as viruses and bacterial spores, providing an ultra-clean air environment for food processing. For example, in dairy or bakery production facilities, where hygiene requirements are extremely high, high-efficiency filters ensure that the air contains minimal microorganisms, effectively preventing food contamination and spoilage.

Since filters are essential components of dust-free rooms, the air filters for such rooms should be selected based on the different levels of air cleanliness required. Do you know the requirements for installing filters in cleanrooms?

1.Before installing HEPA filters and primary efficiency air filters, the cleanroom must be thoroughly cleaned. If the air conditioning system has dust, a medium-efficiency filter may be used instead. If the HEPA filter is installed in the technical mezzanine or ceiling, the mezzanine or ceiling should also be thoroughly cleaned and wiped.

2.After the cleanroom and air conditioning purification system meet cleanliness requirements, the air conditioning purification system must be tested. After running continuously for more than 12 hours, the cleanroom should be cleaned again before HEPA filters are installed.

3.The transportation and storage of HEPA filters should follow the directional markings provided by the manufacturer. During transport, air conditioning filters should be handled gently to prevent severe vibration and collisions.

4.Before installing high-efficiency filters, they must be unpacked and inspected for appearance on-site.

For food factories, it is crucial to select and match purification equipment according to different production processes and cleanliness requirements. With extensive industry experience, Jin Jue Filter Co., Ltd. can customize professional purification equipment solutions for food factories, helping food companies create safe and high-quality production environments, ensuring that every food product is manufactured under clean and contaminant-free conditions.