In the rapidly advancing field of biotechnology, maintaining pristine environmental conditions is undoubtedly a significant factor contributing to the success of research. Among the key elements that ensure this environmental integrity, High-Efficiency Particulate Air (HEPA) filters stand as unsung heroes, providing essential clean air to the biotechnology sector.

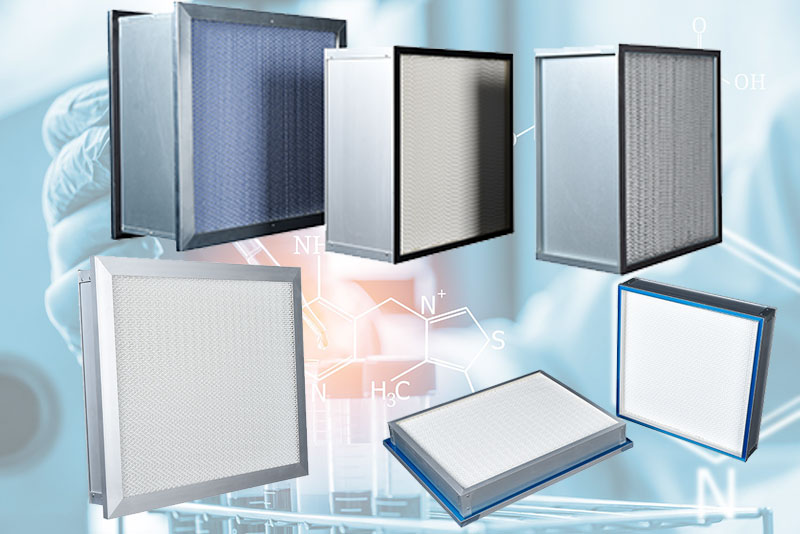

HEPA filters are characterized by their ability to capture particles as small as 0.3 microns with 99.97% efficiency. This remarkable feature has led to their extensive application in the biotechnology industry. The primary function of HEPA filters is to create and maintain sterile environments required for sensitive experiments, pharmaceutical production, and various biological processing procedures.

One of the main applications of HEPA filters in biotechnology is in cleanrooms. These controlled environments demand extremely low levels of particulate matter in the air to prevent contamination of biological processes. Serving as the frontline defense, HEPA filtration systems work tirelessly to remove dust, microorganisms, spores, and other particles that could compromise experiments or production batches.

HEPA filters play a vital role in meeting the stringent requirements for sterility in pharmaceutical production areas. From drug synthesis to packaging, every step necessitates a contamination-free controlled environment. Air filtered through HEPA systems provides the essential assurance of quality and safety for pharmaceutical products.

Bioprocessing facilities, where cell culture, fermentation, and genetic manipulations occur, heavily rely on HEPA-filtered air. Any foreign particles can disrupt these delicate processes, affecting the viability and purity of the final products. HEPA filtration ensures a stable, uncontaminated environment for these critical operations.

Additionally, in research laboratories focusing on genetic engineering, tissue culture, or infectious disease studies, HEPA filters protect researchers from potential hazards while preventing cross-contamination between experiments.

The continuous evolution of biotechnology challenges the boundaries of scientific precision. Consequently, HEPA filters must also evolve. Breakthroughs in nanotechnology have driven the development of more advanced filtration systems, such as Ultra-Low Penetration Air (ULPA) filters. These innovations enhance protection for sensitive biological processes by capturing particles as small as 0.12 microns.

HEPA filters have proven to be indispensable tools in safeguarding the integrity and safety of biotechnology operations, enabling the industry to reach new heights in innovation and precision.

HEPA filters have proven to be indispensable tools in maintaining the integrity and safety of biotechnology operations. Their presence enables the industry to achieve new heights in innovation and precision.