Oil-Water Separator (with Automatic Drainage) + Air Filter: Core Information Summary I. Core Function Solves the three major problems of water, oil, and impurities in compressed air, avoiding equipment damage (30%-50% reduction in service life), product scrapping, and energy waste (15%-20% additiona......

Oil-Water Separator (with Automatic Drainage) + Air Filter: Core Information Summary

I. Core Function

Solves the three major problems of water, oil, and impurities in compressed air, avoiding equipment damage (30%-50% reduction in service life), product scrapping, and energy waste (15%-20% additional consumption). Suitable for industries requiring clean air supply such as automobile manufacturing, electronics, food, and medical care.

II. Core Component 1: Oil-Water Separator (with Automatic Drainage)

1. Core Functions

Adopts "cyclone centrifugation + gravity sedimentation" to separate 99% of liquid oil/water (removes oil droplets/water droplets ≥5μm);

Automatic drainage (float-type: liquid level control, zero air consumption; electronic timing: set cycle on demand), eliminating the need for manual inspection.

2. Key Advantages

High pressure resistance (0.1-1.6MPa), corrosion resistance (aluminum alloy chamber), and no air consumption waste.

III. Core Component 2: Air Filter

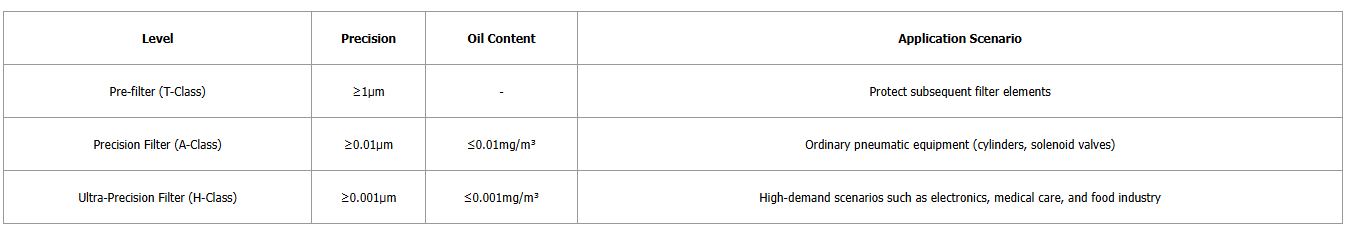

1. Filtration Classification (Three-Stage Purification)

2. Key Advantages

Multi-layer filter element (pre-filtration + ultra-fine fiber + hydrophobic and oleophobic layer) for accurate interception;

Equipped with a differential pressure gauge to indicate filter element replacement, quick-detach structure (filter element replacement in 1-2 minutes), and visible housing for some models.

IV. Combined Application Logic

Air Compressor → Oil-Water Separator (liquid oil removal) → Pre-filter (coarse filtration) → Precision/Ultra-Precision Filter (fine filtration) → Output of qualified clean air.

V. 3 Key Selection Points

Processing Flow Rate: ≥ Air compressor displacement;

Filtration Precision: Select according to industry requirements (e.g., H-Class for electronics industry);

Working Condition Adaptation: Pressure/temperature range covers actual working conditions (select frost-resistant drain valve for low-temperature environments).

VI. Core Value Summary

It extends equipment service life, improves product quality, reduces energy consumption and operation & maintenance costs, and serves as a core solution for industrial air supply purification.